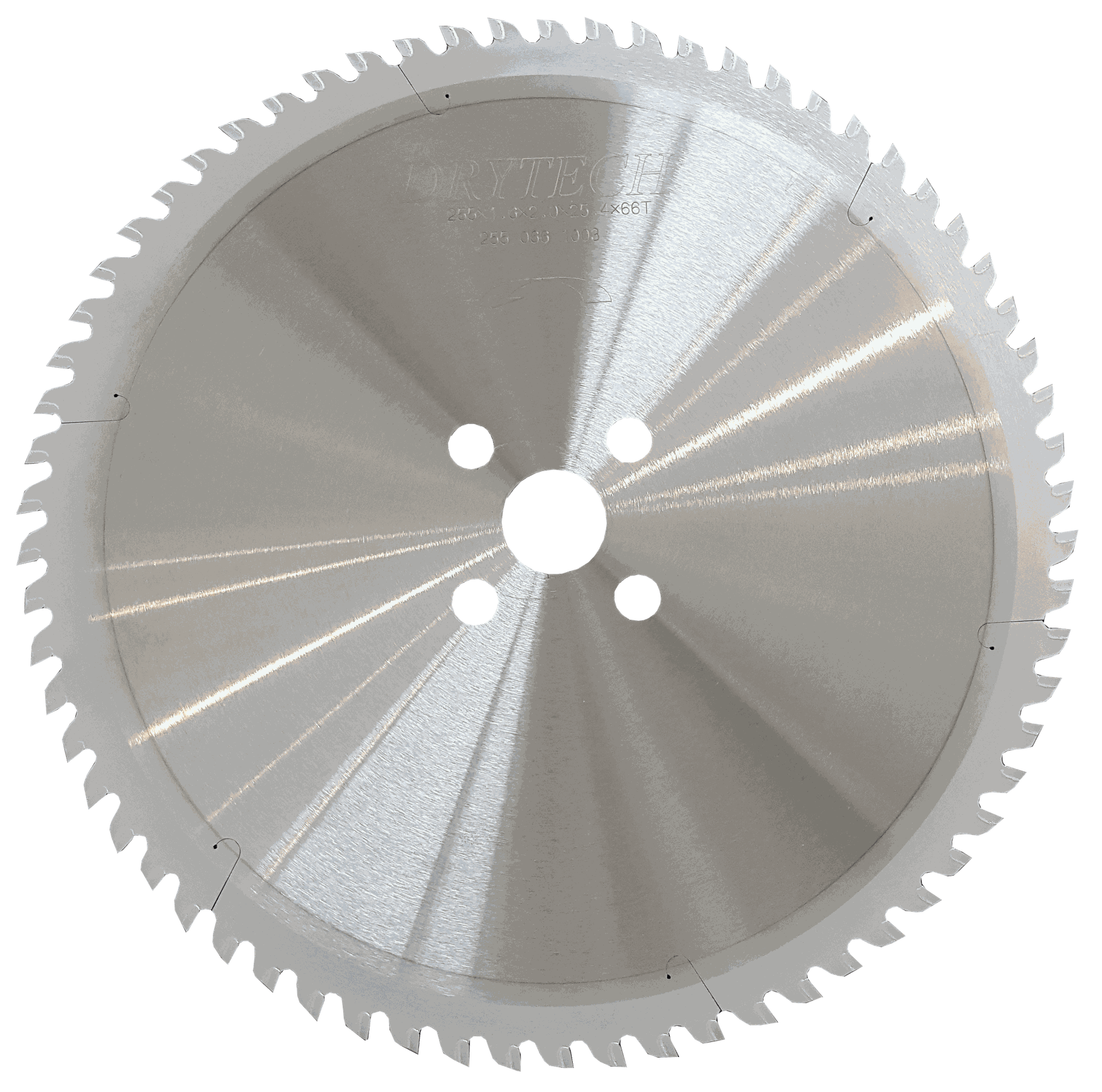

DRYTECH ® TCT Saw blades Special INOX

TCT Saw blades for INOX DRYTECH® Coating

• Cutting of stainless steels

• Up to 3 times higher durability

• No tarnishing of materials

• Lower friction

• Lower cost than standard saw blades

An aluminum-titanium-chromium-nitride coating for special applications in cutting material which

tends to stick.Due to the smooth CrN-surface, the tendency for cold welding can be reduced significantly. The silver colored coating has a high hardness and high oxidation resistance.

DRYTECH® Coating in figures:

• Material: Aluminum titanium chromium nitride,AlTiCrN (stacked)

• microhardness HV 0,05: 3.000 ± 300

• Coefficient of friction against steel 100Cr6: 0,4

| Saw blade diameter | 230 -560 [mm] |

| Cutting capacity | Ø 6 - 180 [mm] |

| Cutting speed | max. 1800 [m/min] |

| Feed Speed | max.6000 [mm/min] |

| Kerf | 2,0 -3,6 [mm] |

|

Center & pin holes

|

customized

|

DRYTECH ® TCT Saw blades for Steel, INOX & Non Ferrous

Carbide or cermet tipped saw blades are suitable for high speed stationary semi-automatic and full automatic cutting units.

Fast cutting, burr free and without coolant of profiles & pipes

Drytech saw blades are able to cut diverse kinds of material and shapes due to a wide range of different geometries (trims, tubes, shutter profiles, sandwich panels, window profiles and airing profiles etc.). The special tooth shape guarantees a perfect cutting surface and a long cutting life of the blade.

Advantages:

•Shortest cycle times due to high cutting speed

•Material saving through thin cut technology with wall thickness starting from 0.5 mm

•Very high durability

•Excellent cutting quality

•Up to 5 times resharpenable

| Saw blade diameter | 100 -730 [mm] |

| Cutting capacity | Ø 6 - 210 [mm] |

| Cutting speed | max. 1800 [m/min] |

| Feed Speed | max.6000 [mm/min] |

| Kerf | 2,0 -4,0 [mm] |

| Center & pin holes | customized |